Shaping the Future of Food & Beverage Manufacturing

When people ask us “what exactly does inControl do?” the short answer is: we help manufacturers and process industries work smarter, safer, and more efficiently as an industrial automation and control systems partner.

inControl were delighted to be represented by our Sales & Marketing Director, Ian Clarke, at Rockwell Automation’s recent event in Manchester: “Shaping the Future of Food & Beverage Manufacturing.”

The day brought together industry leaders, OEMs, and system integrators to explore how AI and digital transformation in food and beverage manufacturing are set to redefine operations in the years ahead.

Insights from Rockwell’s State of Smart Manufacturing Report

Rockwell Automation presented findings from their 10th annual State of Smart Manufacturing Report, which surveyed over 1,500 manufacturing decision-makers worldwide. The report highlights how forward-thinking manufacturers are already using automation, data, and AI to drive measurable performance gains — and where the biggest opportunities still lie.

A keynote session from Al Peasland, former Head of Technical Partnerships at Williams F1 and Red Bull Racing, offered a powerful perspective from motorsport. Red Bull’s engineers, he noted, made 30,000 design changes to gain just one second per lap — a reminder that in manufacturing, as in racing, marginal gains can add up to transformational results.

Our Four Key Takeaways

Reflecting on the day, Ian Clarke commented:

“Food & Beverage manufacturers face a common industry challenge: with a few exceptions such as quality inspection, they cannot fully gain the benefits of AI without upgrading legacy operational technology systems and embarking on a program of smart connected machines and processes. That requires investment and a strong vision from senior leadership.”

From the event sessions and discussions, our team identified four themes shaping the next chapter of smart manufacturing:

- AI’s top near-term use case is quality control, particularly in automated visual inspection, where results are already tangible.

- Manufacturers want to see AI in action — real, live examples rather than theory or slides.

- Three of the top five internal barriers to digitalisation can be addressed through partnerships with skilled systems integrators, closing the gap between IT and operational technology.

- Continuous improvement delivers competitive advantage. Like F1, industrial operations thrive on iterative innovation and precise execution.

Across all job roles, perceptions of the biggest internal obstacles have changed, and whilst the challenges differ across regions, the top 5 concerns were easy to identify

Building Digital Foundations for AI Success

At inControl, we believe that AI and digital transformation in food and beverage manufacturing depend on robust foundations — modernised control systems, secure industrial networks, and seamless OT/IT integration. These are the essential enablers of Industry 4.0, and where the journey toward real digital maturity begins.

Frameworks like the Smart Industry Readiness Index (SIRI) are powerful tools for benchmarking progress, identifying gaps, and defining a clear roadmap for transformation. As certified SIRI assessors, inControl helps manufacturers measure their digital readiness and prioritise actions that deliver lasting operational improvement.

Partnering for Progress

Together with technology partners such as Rockwell Automation, inControl is supporting the Food & Beverage sector’s transition toward connected, data-driven manufacturing — turning digital ambition into measurable performance.

🔗 Download Rockwell’s State of Smart Manufacturing Report

🔗 Explore how SIRI can help your business begin its digital transformation journey

Ian Clarke – travelling from Manchester Piccadilly Station to Rockwell’s event at the IWM North.

inControl: The best batch yet

How inControl Supports Food & Beverage Manufacturers

As a trusted industrial systems integrator, inControl helps Food & Beverage businesses modernise their production processes, improve consistency, and prepare for digital transformation.

Our expertise includes:

- Brewery and distillery automation – from recipe control to traceability

- Batch and process control systems – delivering precision and repeatability

- OT/IT integration – unlocking real-time production data for smarter decision-making

- Smart Industry Readiness Index (SIRI) assessments – benchmarking digital maturity and building clear roadmaps for Industry 4.0

These capabilities enable manufacturers to improve efficiency, reduce waste, and create the connected foundations needed for AI and smart manufacturing technologies to succeed.

“Food & Beverage manufacturers face a common industry challenge: with a few exceptions such as quality inspection, they cannot fully gain the benefits of AI without upgrading legacy operational technology systems and embarking on a program of smart connected machines and processes. That requires investment and a strong vision from senior leadership”

Ian Clarke, Sales & Marketing Director, inControl

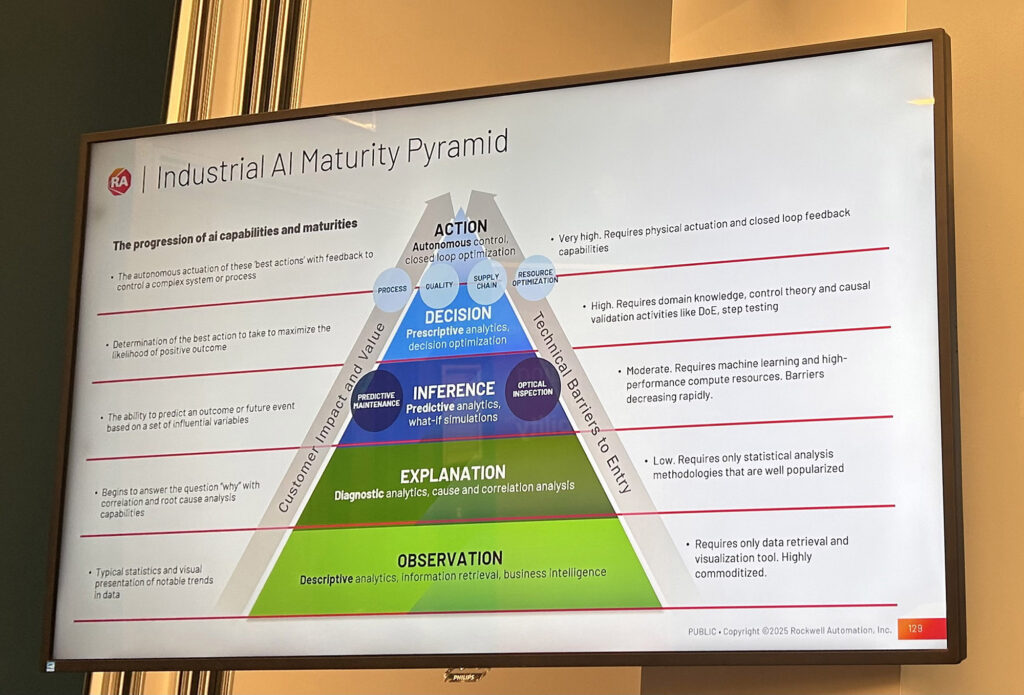

A slide demonstrating the importance of tracking the maturity of AI in the sector