Supporting your Digital Transformation journey Smart Connected Machines and Factories

The fourth industrial revolution, Industry4.0 or simply using digital data and methods to improve your business, this is an area that we are experts in. There is significant mystique and marketing around this topic, that will make you ask questions such as “can we see a clear ROI?”, “do we have the right skills?”, “is the technology available yet?”, “is our equipment too old for this?” and many other concerns.

InControl Systems are here to simplify that discussion, and to make sure you can develop an affordable ‘proof of value’ and then support you in your first steps along the journey.

Made Smarter or Industry 4.0

Most business leaders and senior managers will be aware that if only they had the right data, in the right place at the right time, they could avoid huge unexpected costs, and improve the productivity and quality of their business. But the time taken to collect all this data is huge and it’s nearly always old data, too old to make a difference.

Where InControl can help is to use standardised methods of connecting to your machines and processes (whatever the age or condition), and provide that data throughout your business, to your ERP & MRP systems, as well as to people responsible for:

- Quality improvement & SPC

- Predictive Maintenance

- Production Planning

- Energy Management

- Facilities Management

On top of this, imagine the benefits of being able to automate your entire order system. With LOB (Line Of Business) integration, order requests enter your system virtually to produce the order. Works orders and stock are then coordinated with your manufacturing in an instant. Our systems can even control the scheduling of your staff, and your shift modules, and optimise all the equipment used.

Bridging Information Technology (IT) with Operational Technology (OT)… Seamlessly

At InControl, we not only have the engineering and IT expertise to integrate these systems, but also to spell out the benefits to engineering and IT staff. This goes a long way toward bridging the void that often exists between these two departments.

Start small and scale, standardise and stay vendor independent – we’re your Industry4.0 partners

We believe in not ‘boiling the ocean’, but starting with a small proof of value pilot project, at the same time as introducing smart and resilient standards so that you can scale and replicate easily. Either across processes, departments, or across sites and countries. And what’s more, you need to develop solutions that are vendor agnostic, because most of your machines and processes will have different automation & controls within, and you also want to keep your options open for the future.

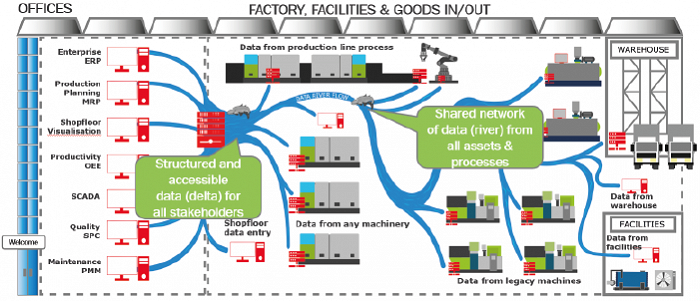

Creating a Digital River & Delta for your business

Many businesses start with a ‘siloed’ project and then over the years develop a number of other ‘digital’ projects in isolation.

At InControl, we recognise that many departments require data from the same machines & processes and often the same data, but for different purposes.

But this is an inefficient way to develop a Digital Roadmap, so we recommend developing the flow of a digital river throughout your business first, and then starting with a pilot project or a proof of concept.

This way you build the data structure and standards in the business so that you can grow your capabilities as you tick off your own priorities as you develop your digital maturity

Digital standards and naming conventions

InControl is masters in helping you develop scalable and vendor-agnostic standards, specifications, and naming conventions for your digital assets and sensors. We would support you in this crucial aspect of your journey so that you have a professionally developed set of standards, that can be rolled out to multiple machines, processes, factories, and global locations.

Digital consultation workshops

No one knows your business better than you and your staff. InControl Systems can help facilitate workshops to identify priorities, challenges, and critical data points that will be input to your digital transformation projects and ensure that you capture and analyse data that can help you improve your business productivity, profitability, and reputation.